| |

|

||

| |

|

Go ahead, make a move!

|

|

The

Character Shop creates a robot to help support your health.

What's New

| Features |

Commercials | Resume | Realistic | Whimsical

| Scary | Animatronics

| Prosthetics | Puppets

| Waldo ® | Publicity

| TCS Fun | FX FAQ

| Reference | Contact

Us Photographs

on this pages used by permission. Except

where otherwise noted, all contents are the property of The Character

Shop, Inc.

and copyright 2018

Go ahead, make a move!

So, the challenge was: how does

Kineticor

promote and sell this technology? By hiring Rick Lazzarini and the

talented Artists and Technicians at The Character Shop to create a very

realistic, very specialized robot. One that lays in an MRI bed

and…moves the way an MRI patient would. 4 different types of

pre-programmed moves, each selectable, that demonstrate how a real

human might move…which allows Kineticor to apply their solution and

show how they’ve solved this problem.

Kineticor’s

Jeffery Yu, in coordination with Siemens, provided the specifications

from which The Character Shop worked: It was to be a Female human

replica, believably realistic, with a flexible skin, just the torso, no

arms, no legs, clad in a polo shirt, and remotely controlled to perform

4 different types of typical movement: Shifting, Nervousneness, Falling

Asleep, and even display a slight tic/tremor with Dystonia (which

actress Katherine Hepburn famously exhibited in her later years).

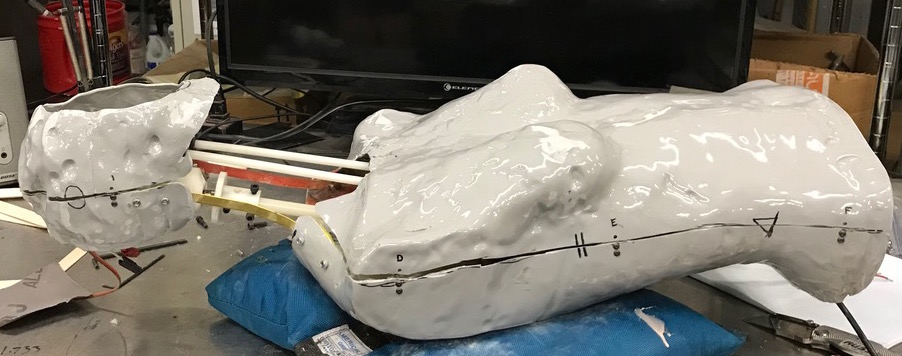

The TCS team started out with a choice of basic female forms, then

modified the Client’s choice until approved. From that, a master

Silicone mold and Epoxy/glass jacket was made. The mold was cleaned,

released and prepared then a special mix of silicone, having just the

precise durometer, tint, and thickness was made. This formed the

robot’s outer skin.

Another epoxy and fiberglass shell was made to serve as her inner

‘skeleton”, or shell, to house the battery, circuit boards, and

actuators needed internally. All the mechanisms had to be

self-contained.

In the meantime, 3D mechanical designs were worked on and completed in

Autodesk Inventor, with working 3D imagery being able to be run “live”

through their motions to simulate what they would do in real life. From

the dimensions and structures depicted in the Inventor files, actual

mounts , couplers, plates, and parts were machined out of Delrin

engineering plastic. Meanwhile, actuators were spec’ed, ordered, and

installed into the inner structure. Two linear actuators provided Head

Up/Down and Head Tilt movements, while a rotary actuator provided head

turning Left/Right. Each actuator was mounted compliantly, to give as

natural a motion as possible, and that included the use of nylon rods,

which flex the way human spinal columns do.

The result was a solid success, with enthusiastic approvals from

Kineticor and Siemens alike. The Character Shop’s experience in

blending Technology and Art has benefitted many films and commercials,

and it’s clear that it can benefit Medical Technology as well.

Home

Photographs and text may only be re-published with written permission.

All rights reserved.